Understanding the Differences Between Types of Consolidating Rollers

When working with glass-reinforced plastic (GRP) and other composite materials, the right tools can significantly enhance both the quality and efficiency of your projects. Consolidating rollers are essential in ensuring proper adhesion, removing air bubbles, and achieving a smooth finish. In this blog, we'll explore the various types of consolidating rollers, highlighting their unique features and best applications.

Paddle Roller - Made from lightweight aluminium extrusion - screw type fixing

- General use / universal roller for most GRP applications

- Well suited for bi-directional / combination / chopped strand mat / uni-directional fabrics

- Robust horizontal profile for effective air removal

- Suitable for large surfaces

- Wide range of sizes available

- Resistant to many cleaning solvents

|  |

|

Bristle Roller - Manufactured from natural black bristles in a spiralled construction –push type fixing

- Efficient air removal from penetrating action of bristles

- The bristles allow for a smooth finish

- Excellent for uneven and curved surfaces

- Effective air bubbles and pin-holes elimination

- Widely used for layup of boat hulls and chemical tanks

- Well suited for thin laminates, carbon fibres and epoxy resins

- Push type fitting for quick removal of the sleeve from the handle

- Resistant to many cleaning solvents

|

Radius / Corner / Disc Roller - Solid Aluminium construction – rivet type fixing (non-removable)

- Primarily used for consolidating corners during layup

- Suitable for all resins and glass fibre fabrics

- Easy to clean

- Resistant to many cleaning solvents

|  |

| Bubble Buster Roller - Made from lightweight v-notched aluminium extrusion - screw type fixing

- Effective reduction of spray due to notched extrusion

- Notches allow better movement of fibre

- Well suited for chopped strand / sprayed roving

- Effective air removal

- Suitable for large surfaces

- Wide range of sizes available

- Resistant to many cleaning solvents

|

Aluminium Finned Roller - Manufactured from solid aluminium – Vertical Finned - screw type fixing.

- General use roller with well-spaced fins for excellent air relief

- Vertically machined grooves for reduced spray

- Consistent finish with low tendency of fibre movement

- Light weight and easy to use

- Resistant to many cleaning solvents

|  |

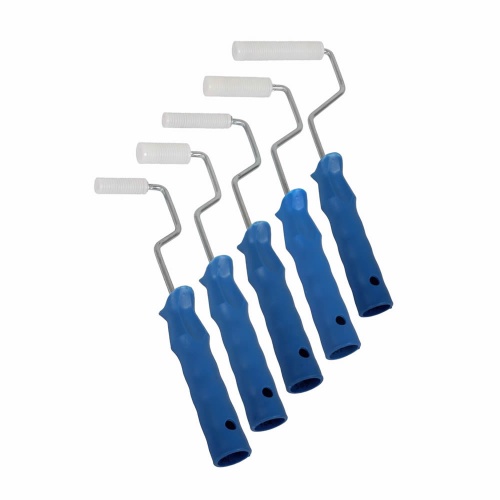

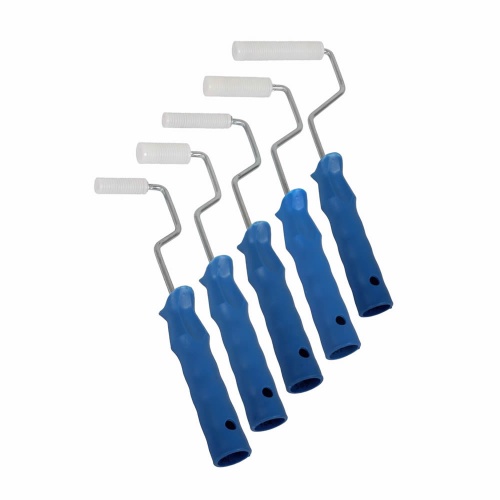

| Plastic Finned Roller - Manufactured from PTFE – Vertical Finned - screw type fixing

- Suitable for low viscosity resins thin aramid / carbon / glass fabrics

- Non-stick properties

- Vertically machined grooves for reduced spray

- Reduces breakage of glass fibres with low tendency of fibre movement

- Ideal for light weight exotic materials such as aramids / carbons / light weight glass fabrics etc.

- Leaves no marks on the material

- Resistant to many cleaning solvents

|

Conclusion

Whether you need a versatile paddle roller or a specialized bristle roller, understanding these differences will help you choose the best tool for your next project. For more information on consolidating rollers and to explore our product range simply click the images of the consolidations rollers in this blog or visit mbfg.co.uk today!